What is polishing

Written by: Vinnie van Rooij

Polishing is the act of using a light abrasive product to remove a very thin layer from the surface that gets polished. Usually this process is preceded by a very thorough cleaning of the surface.

There are products to polish paint, glass, plastic, Perspex, metal and other solids.

Contents

How it works

polishing removes a very thin layer, is a surface imperfection is deeper than the polish can remove, the surface imperfection can still be visible, although the removal of part of the imperfection will have made it less visible.

For example, if a surface imperfection is 10 micron thick, and by polishing you can only remove 7 micron, there will still be 3 micron left. Although the imperfection is 7 micron less deep and probably a lot less visible, it might still be visible.

Gradations

polish comes in several different grades. The most common grades are:

Finishing polish

Light polish

Medium polish

Cutting polish

Heavy cutting polish

Compounds

The amount of result is very dependent on the surface it is used on. Some paint can be tougher than other paint. A very tough paint needs a rougher polish to achieve affect. That same grade of polish will have much more result on softer paint.

The polishingpad that is used with the polish also has a big effect on the result.

Compound

A polish that is designed to remove deep marks and leaves a finish that needs refining is also referred to as a compound. These are rougher, remove more of the surface it’s used on and always need several refining steps to get a proper finish. Compound are almost always SMAT polish.

SMAT and DAT

polish is made out of a few ingredients. Most common is an oil to help lubricate and an abrasive material (usually a powdery substance).

SMAT = Super Micro abrasive Technology

SMAT uses micro abrasives of a fixed size for a controlled and even effect. These abrasives stay this size. Which means that more passes will have more effect. In essence: the longer you polish, the more effect it will have (because you remove more paint). There is a limit to how long it lasts because the micro abrasives in the polish can be deformed by the polishing-action, making them less effective. Stop polishing when you have achieved the desired result.

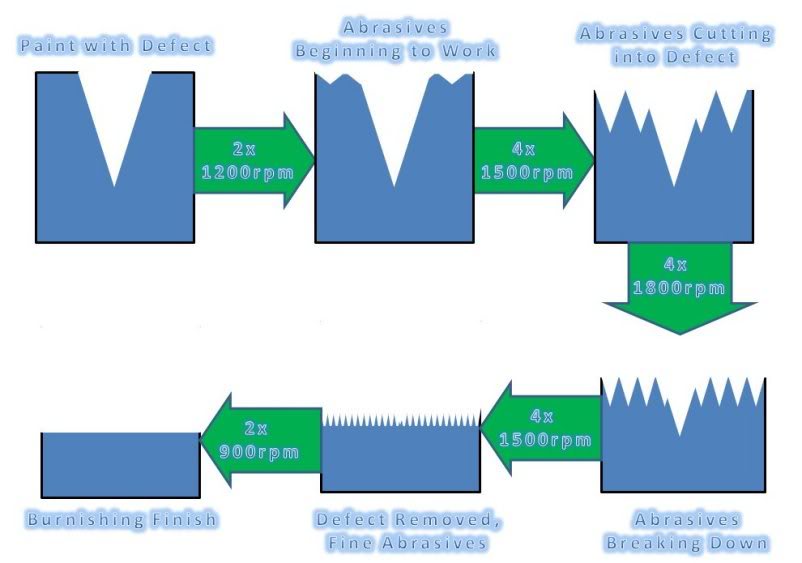

DAT = Diminishing abrasives Technology

DAT uses abrasives that break down while using. A combination of pressure, heat and time causes the abrasives in the polish to become smaller and smaller. They get pulverized and disintegrate into nothing. After a certain time, the polish will have no effect anymore, regardless of the passes you make. It is highly recommended to work in the polish until it is completely disintegrated.

DAT may offer less cutting power then SMAT, but they finish with a surface that needs much less refinement. In some cases you can actually achieve a finishing result with 1 polish.

polishing by hand or machine

polishing or paint correction can be done by hand or machine. polishing by hand means that you have more control, can get into smaller areas and can actually “feel” how the pad responds on the paint.

polishing by machine has the benefit that it works much faster, gets warmer (which helps a polish to break down) and it’s easier to work on a bigger area (preventing difference between polished areas).

The downsides with polishing by hand are obviously the manual labor, the possible need for special hand polishing-pads and the time it needs to achieve the desired result.

When polishing by machine you need to buy a machine (which can be expensive), you need to watch out for heat buildup, clogged pads and not to hit corners.

Polishing by hand can either refer to applying polish with the bare hands, or by moving the polishing pad by hand instead of using a machine polisher. This article describes the latter....

Polishing by hand can either refer to applying polish with the bare hands, or by moving the polishing pad by hand instead of using a machine polisher. This article describes the latter.... The DA (Dual Action) polisher is considered by many to be the machine to use if you are new to machine polishing, though as discussed elsewhere, this is not always the case - rather, you should try wherever possible to try both styles of machine (DA and rotary) and see which suit your style the best as many will find the vibrations of DA polisher unsettling and this struggle with the control of the machine can actually make it more dangerous than the smoother rotary....

The DA (Dual Action) polisher is considered by many to be the machine to use if you are new to machine polishing, though as discussed elsewhere, this is not always the case - rather, you should try wherever possible to try both styles of machine (DA and rotary) and see which suit your style the best as many will find the vibrations of DA polisher unsettling and this struggle with the control of the machine can actually make it more dangerous than the smoother rotary.... It is often asked on detailing fora and social media: "what is the best coating". Off course there is a difference between certain products and brands, but it is important to know what you are asking. In this guide I will try to explain what the problem is with this question unless it is asked more in-depth....

It is often asked on detailing fora and social media: "what is the best coating". Off course there is a difference between certain products and brands, but it is important to know what you are asking. In this guide I will try to explain what the problem is with this question unless it is asked more in-depth.... When removing paint defects, like scratches or water spot etching, the Kevin Brown Method uses a Finishing Polish instead of the traditional heavy-cut compound. This is done via a combination with a microfiber polishing pad and a random orbital polisher....

When removing paint defects, like scratches or water spot etching, the Kevin Brown Method uses a Finishing Polish instead of the traditional heavy-cut compound. This is done via a combination with a microfiber polishing pad and a random orbital polisher.... Paintwork can, in some cases, become oxidized. Making it turn matte and slightly fade color. If untreated, it can eventually cause the lacquer and/or paintwork to completely fail. It is most common on red cars, but it can happen with every color....

Paintwork can, in some cases, become oxidized. Making it turn matte and slightly fade color. If untreated, it can eventually cause the lacquer and/or paintwork to completely fail. It is most common on red cars, but it can happen with every color.... WOWO's is a brand of detailing products from Glasgow, United Kingdom. The brand makes and sells detailing products varying from waxes to shampoo and other cleaners. WOWO's is fairly unique in that it is almost a one-man operation....

WOWO's is a brand of detailing products from Glasgow, United Kingdom. The brand makes and sells detailing products varying from waxes to shampoo and other cleaners. WOWO's is fairly unique in that it is almost a one-man operation....

[…] je meer lezen en leren over polijsten? Dan kun je altijd nog dit handige artikel doorlezen op DetailingWiki voor meer […]

[…] van "detailen". Mocht je geprikkeld zijn om dieper in deze wereld te duiken, dan is DetailingWiki een mooie plek om te […]

[…] van "detailen". Mocht je geprikkeld zijn om dieper in deze wereld te duiken, dan is DetailingWiki een mooie plek om te […]